Peroxide products used in Arkema's solar encapsulation films:

- High quality and purity; fast crosslinking and high efficiency;

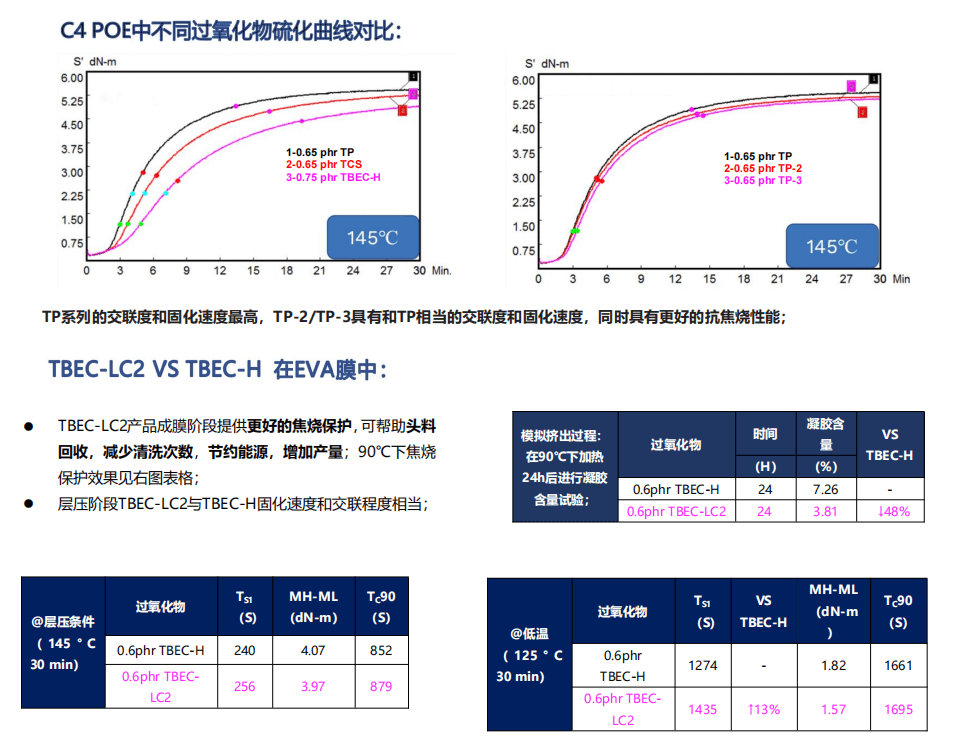

- Improved crosslinking degree and speed in POE crosslinking and less dosage;

- Excellent anti-scorch properties; helps in extruded film recycling, improving lamination process, etc;

| Product Model | dominance | EVA | POE | EPE |

| Luperox? TBEC-H | High purity (≥98.5%), low ionic content (e.g. CL-, NA+); | √ | √ | √ |

| Luperox? TBEC-LC2 | Better scorch protection than TBEC-H, which aids in header recycling, reduces cleaning, saves energy and increases production; | √ | √ | √ |

| Luperox? TCS | Fast curing extended glue burning product, in POE C4 provides better crosslinking degree and faster crosslinking speed and less usage than TBEC-H; | √ | √ | √ |

| Luperox? TP | It provides the fastest cross-linking degree and cross-linking speed in C4 of POE and less dosage; in EPE, it can synchronize the cross-linking of EVA and POE; | √ | √ | √ |

| Luperox? TP-2 | It has the same cross-linking degree and curing speed and dosage as TP, and at the same time has better anti-scorch performance than TP; | √ | √ | √ |

| Luperox? TP-3 | It has the same cross-linking degree and curing speed and dosage as TP, and at the same time has better anti-scorch performance than TP-2; | √ | √ | √ |