Product Name: LUPEROX? F40P-SP2

Chemical name: Di(tert-butylperoxyisopropyl) benzene

CAS No.: 25155-25-3

Product Description:

Luperox? 40P-SP2 is a char protection product for Luperox? F40P. It is a dispersion of calcium carbonate and silica at 40%. It is specially designed to provide good burn-in protection for all kinds of rubbers including EPDM, HNBR, CPE, etc. in extrusion molding, and its chemical structure formula is:

1,3 1,4-Bis(tert-butylperoxyisopropyl) benzene

Molecular weight: 338.5 g/mol

Main properties

Form: Powder

Peroxide content: 40%

Active oxygen content: 3.8%

Scorch protection

Luperox? 40P-SP2 provides excellent burn-in protection and solves the disadvantages of conventional antioxidants.

As shown in Figure 1, the main advantages over conventional antioxidants are:

It traps free radicals relatively quickly to provide good char protection;

Comparable cross-linking levels (cross-linking levels are not reduced).

performances

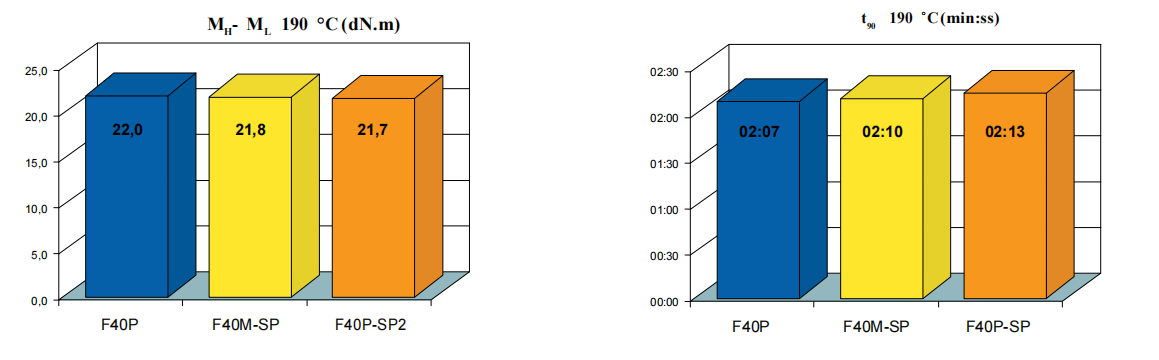

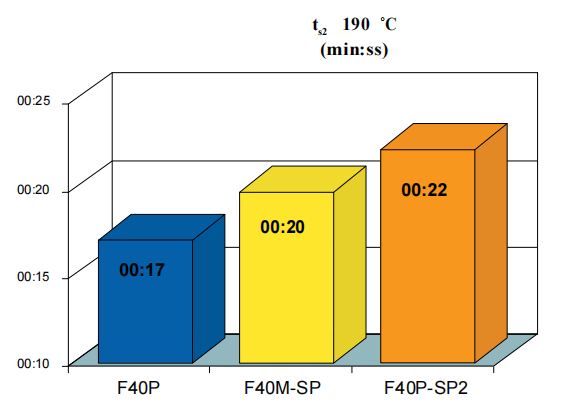

The vulcanization properties of Luperox? F40P-SP2, Luperox? F40P and Luperox? F40M-SP in EPDM (EPDM DUTRAL TER 4049) compounds are as follows. The peroxide content was 8 phr.

Luperox?F40P-SP2 and Luperox?F40M-SP have extended protection time or "scorch time at vulcanization temperature" (t s2at 190°C) by 30% and 18% respectively compared to Luperox?F40P.

Excellent scorch protection measured at 145°C for Menni Viscosity Modifiers.

The char protection time t s05 of Luperox? F40P-SP2 is 3 times higher than that of Luperox? F40P.

vantage

The excellent scorch protection offered by Luperox? F40P-SP2 offers many advantages.

reduce costs

Luperox? F40P-SP2's inherent excellent char protection reduces the amount of antioxidant used in the formulation.

mixed martial arts training

Productivity can be increased by increasing the mixing rate.

The two-step blend can be changed to a one-step blend.

Good scorch protection extends the mixing time and results in a more homogeneous mix.

vulcanization (curing rubber using sulfur and heat)

In injection molding, a longer protection time reduces scrap. Mould design can be optimized (more cavities): more productive and more suitable for peroxide vulcanized rubber products. In addition, higher mold temperatures can be used to increase productivity: faster mold filling, faster vulcanization.

In extrusion processing, both extrusion temperature and speed can be increased as a way to increase productivity. Good burn-in protection reduces downtime for cleaning equipment (gels) and increases production time.

major application

Luperox? F40P-SP2 has been specially developed for processes such as injection molding or vulcanization of reactive polymers (HNBR or CPE) that require strict burn-in protection. As a result, it can be applied to a wide range of products. For example:

-

- O-ring; O-ring; O-ring; O-ring

-

- Molded products.

-

- Hoses and window frames.

-

- Rubber seals and gaskets.

-

- Wires and cables.

-

- EPDM and EVA soles.

additive quantity

Typical additive levels for Luperox? F40P-SP2 are listed in the following table.

EPDM: 6 - 12

HNBR: 6 - 10

CPE: 4 - 8

decomposition product

Main decomposition products of Luperox? F40P-SP2 in inert media

Same as F40P.

-

- Acetone.

-

- tert-Butyl alcohol.

-

- Methane.

-

- Bis(acetophenone)

-

- Bis(isopropyl)benzene.